Stainless steel is essential

Stainless steel in its various grades supports many essential applications in our modern world from transportation, buildings, bridges, water pipes and industrial processes to medical uses, food processing and preparation.

What is stainless steel?

Like all types of steel, stainless steel is not a single metal but an alloy, made from two or more separate elements alloyed or ‘melted’ together.

Stainless steel was invented early in the 20th century when it was discovered that adding a certain amount of the metal chromium (usually a minimum of 10.5%) to ordinary steel gave it a bright shiny finish and made it highly resistant to tarnishing and rusting.

This rust-resisting property which we now call ‘corrosion resistance’ sets stainless steel apart from most other forms of steel.

Stainless steel is the generic name for several grades of steels used primarily for their resistance to corrosion. All contain a minimum of 10.5%, by mass, of chromium. Although other metals, particularly nickel and molybdenum, are added to improve corrosion resistance, chromium is the essential element that makes steel stainless.

Chromium, making steel stainless

The corrosion resistance and shiny lustrous appearance of stainless steel is created by an extremely thin, continuous, chromium-oxide film which spontaneously forms on the surface of the steel, in the presence of air and prevents iron from oxidation.

This film renders the surface inert to chemical reaction, thus protecting the steel from corrosive attack. Should the surface be damaged or scratched, the ‘passive’ layer instantly re-forms. Thanks to chrome, stainless steel literally self-heals. In fact, chrome is the one ingredient that makes stainless steel ‘stainless’ whatever the grade.

Experiments have shown that the corrosion resistance of steel is improved only when the chromium content exceeds 10.5%. So, the chromium content in stainless steel is generally not less than 10.5%, and is around 18% on average.

Alloyed for lasting value

Discover more about the alloys used to make stainless steel.

Self repairing for lasting value

Discover the long-lasting benefits of stainless steel’s corrosion resistance when compared to carbon steel.

Stainless steel is everywhere

Kitchenware and safe food processing

Sanitaryware and outdoor equipment

Architecture, building, construction and urban furniture

Medical environments and equipment

Public water distribution, preventing leakage

Treatment plants for potable and wastewater

Components for automotive and aero engines

Chemical and petro-chemical plants

Fuel and chemical tankers

Manufacturing equipment for food and pharmaceutical products

Stainless steel – a sustainable material

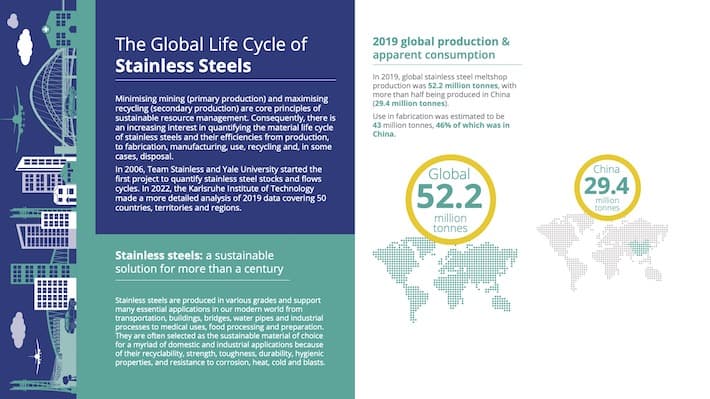

Stainless steel is produced in various grades and supports many essential applications in our modern world from transportation, buildings, bridges, water pipes and industrial processes to medical uses, food processing and preparation. Stainless steel in its various grades is often selected as the sustainable material of choice for a myriad of domestic and industrial applications because of its recyclability, strength, toughness, durability, hygienic properties, and resistance to corrosion, heat, cold and blasts.

Stainless steel is produced in various grades

Discover the various grades of stainless steel, each with different properties suited to different applications.

Recycling stainless steel

Find out more about the recycling of stainless steel.

In addition to these numerous qualities, all types of stainless steel are 100% recyclable. Currently around 95% of stainless steels are recycled at end-of-life, either to become new stainless steel (70%) or used to make new carbon or special steels (25%).

Recycling is highly beneficial both economically and environmentally. The high value of stainless steel scrap makes it worth collecting and sorting, which is why it is recycled at such a high rate.

Reusing its valuable alloying elements reduces cost, resource depletion, environmental impacts as well as energy use. The high end-of-life recycling rate indicates how efficiently stainless steel is recycled from end-of-life products. In principle, and as long as product design and recycling technologies allow, stainless steels can be recycled infinitely. Scrap is a secondary raw material arising from product manufacturing processes as well as from finished products at the end of their life.